TO EFFECTIVELY AND EFFICIENTLY GRANULATE, PULVERISE, MIX, SHRED, PULP, CHOP, DISPERSE A WIDE RANGE OF WET AND DRY MATERIALS. HIGHLY POWER EFFICIENT SIZE REDUCTION UNIT WITH WIDE RANGING APPLICATIONS IN PHARMACEUTICALS, CHEMICAL, FOOD PROCESSING, PIGMENTS, CERAMICS AND OTHER ALLIED INDUSTRIES.

The 'Multi Mill' is a well established 'Comminuting Mill' widely used for 'wet and dry granulations', 'pulverising', 'dispersion' and scrap recovery. This versatile unit produces a highly uniform end product with minimum power consumption.

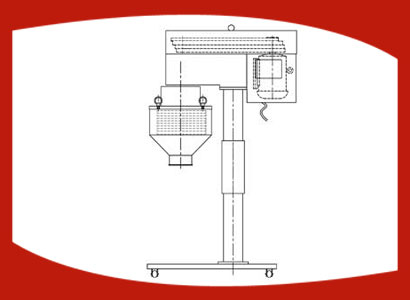

The unit basically consists of a vertical rotor revolving inside a cylindrical screen. Multiple number of hammers (beaters) are pivoted on the rotor and revolve with the rotor, simultaneously having a swinging motion. These beaters have a close tolerance to the 360° cylindrical screen. Also, the beaters have a knife–like cutting edge on one side and a flat edge on the reverse. The cylindrical screen forms the milling chamber.

The feed enters the milling chamber from the top, parallel to the axis – as different from normal hammer mills. The milled / granulated product passes through the perforated screen surrounding the rotor and is collected through the outer hopper.

The construction allows for processing wet, sticky, gummy and flow resistant materials apart from dry powder / granules.

The solid feed can be up to 50 mm in size. The processed material can range from 10 mm to minus 100 mesh, depending on the nature of the feed input, size of screen chosen, speed of rotor, etc.

This compact, portable, economical unit is low on power consumption, has all contact parts in stainless steel, produces highly uniform product, with minimum of 'fines', and can be dismantled, cleaned, and re-assembled within minutes without the use of any special tools.

Multi Mill is ideally suited for processing chemicals, pharmaceuticals, plastics, ceramics, powder metals, pigments, food products, etc.

SPECIFICATIONS:

Model: UMM 250

Model: UMM 250 Motor: 3.0 HP

Motor: 3.0 HP Rotor Diameter: 250mm

Rotor Diameter: 250mm Screen Area (approx): 1100 sq.cm.

Screen Area (approx): 1100 sq.cm. No of beaters: 14

No of beaters: 14 Overall Height: 1800 mm

Overall Height: 1800 mm Floor Space: 1000 X 800 mm

Floor Space: 1000 X 800 mm Net Weight: 290 Kgs

Net Weight: 290 Kgs Shipping Weight: 490 Kgs

Shipping Weight: 490 Kgs Shipping Dimensions: 1175 X 1175 X 2000 mm

Shipping Dimensions: 1175 X 1175 X 2000 mm

* The design of the machine is subject to change from time to time to keep pace with the state of the art ensuring improvement in efficiency and elegance.