MOST EFFECTIVE 'POWDER MIXER' IDEAL FOR USE IN PHARMACEUTICAL, BULK DRUGS, AGRO CHEMICALS, INSECTICIDE, PESTICIDE, VETERINARY, FOOD PROCESSING, SPICE AND ALLIED INDUSTRIES.

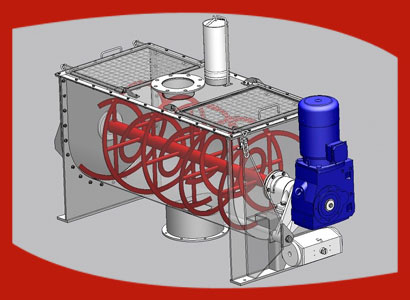

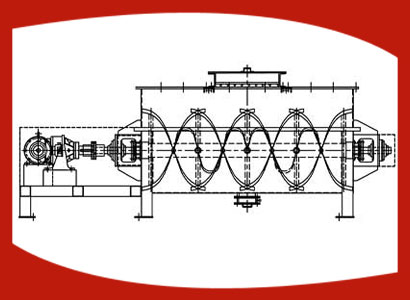

The ribbon blender consists of a horizontal 'U' shaped trough fitted with two concentric ribbon agitators with contra pitches, mounted on a central hollow shaft, promoting center flow triple action movement of central hollow shaft, promoting centerflow triple action movement of material for thorough and homogeneous mixing in very short time cycle.

TROUGH:

The horizontal 'U' trough is with welded end plates and with outboard bearing housings and integral gland housing. The shaft alignments are permanently maintained since the end plates are welded to trough, do not require gaskets or bolting. Consequently, leakages through the gland are greatly minimized.

ROTOR:

The rotor is a carefully engineered piece with double contra action ribbons fabricated and machined in a single setting with taper bore for stub shaft fixing. The ribbons are fully welded on arm pipes (spokes) which are in turn welded to the center hollow shaft, pierced through and through, and welded on either side of the shaft.

The stub shafts are machined to a matching taper and key fitted to the rotor. An axial bolt passes through the stub shaft and rigidly 'U' Clamps longitudinally the stub shaft with the rotor. The rotor maintains close tolerance with respect to the trough achieving efficient mixing.

SALIENT FEATURES:

The ribbon blenders are provided with contra wound, triple action, double ribbons promoting homogeneous mixing in short time cycle.

The ribbon blenders are provided with contra wound, triple action, double ribbons promoting homogeneous mixing in short time cycle. In addition to radial mixing, the outer ribbons axially move the material towards discharge port, while the inner ribbons move the material in the opposite direction.

In addition to radial mixing, the outer ribbons axially move the material towards discharge port, while the inner ribbons move the material in the opposite direction. A homogeneous mix is achieved in short time cycles with optimum power consumption.

A homogeneous mix is achieved in short time cycles with optimum power consumption. Welded trough construction (with no gaskets, bolts) maintaining permanent shaft alignment and is easy to clean.

Welded trough construction (with no gaskets, bolts) maintaining permanent shaft alignment and is easy to clean. Shaft sealing with gland packing arrangements simple to replace without dismantling.

Shaft sealing with gland packing arrangements simple to replace without dismantling. No black particle contamination since concentricity of shaft rotation is maintained permanently and with maintenance free outboard bearings.

No black particle contamination since concentricity of shaft rotation is maintained permanently and with maintenance free outboard bearings.

Drive unit is totally enclosed.

Drive unit is totally enclosed. Can handle variety of materials from fluffy to dense and dry to semi-wet.

Can handle variety of materials from fluffy to dense and dry to semi-wet.

SPECIFICATIONS:

| MODEL | GROSS VOLUME | WORKING VOLUME | TROUGH DIMENSIONS IN MM | THICKNESS | POWER | ||||

|---|---|---|---|---|---|---|---|---|---|

| URB | Ltrs | Ltrs | LENGTH | BREADTH | DEPTH | H.P | |||

| URB 75 | 80 | 40 | 750 | 300 | 400 | 2MM | 1.0 | ||

| URB 150 | 150 | 75 | 850 | 400 | 60 | 2MM | 3.0 | ||

| URB 250 | 250 | 150 | 1000 | 450 | 600 | 2MM | 3.0 | ||

| URB 400 | 450 | 225 | 1275 | 550 | 710 | 2MM | 5.0 | ||

| URB 600 | 660 | 330 | 1500 | 600 | 800 | 3MM | 7.5 | ||

| URB 1000 | 1150 | 550 | 1800 | 750 | 950 | 3MM | 10.0 | ||

| URB 1500 | 1500 | 750 | 2000 | 800 | 1025 | 3MM | 15.0 | ||

| URB 2000 | 2000 | 1000 | 2250 | 900 | 1100 | 4MM | 20.0 | ||

| URB 2500 | 2750 | 1350 | 2500 | 1000 | 1250 | 4MM | 25.0 | ||

| URB 3000 | 3400 | 1700 | 2500 | 1100 | 1350 | 5MM | 25.0 | ||

| URB 4500 | 4750 | 2350 | 3000 | 1200 | 1450 | 5MM | 30.0 | ||

| URB 7000 | 7000 | 3500 | 3500 | 1400 | 1600 | 6MM | 40.0 | ||

| URB 9000 | 9000 | 4500 | 3750 | 1500 | 1775 | 6MM | 50.0 | ||

| URB 12500 | 13000 | 6500 | 5000 | 1600 | 1800 | 6MM | 60.0 | ||

| URB 18000 | 18000 | 9000 | 5000 | 2000 | 2300 | 8MM | 75.0 | ||

* The design of the machine is subject to change from time to time to keep pace with the state of the art ensuring improvement in efficiency and elegance.