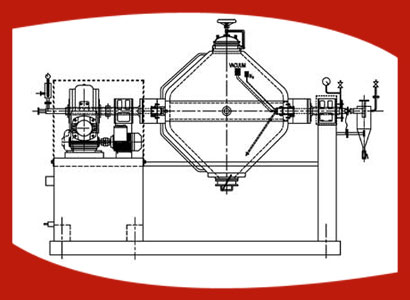

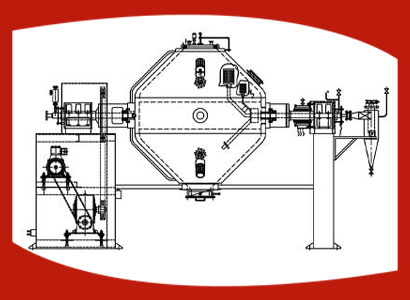

The Rotary Cone Vacuum Dryer consists of a Jacketed Double Conical Shell rotating around 6 RPM with provision for application of vacuum inside the shell and circulation of heating media in the jacket during the rotation of the cone. The large heating surface area presented by the internals of the cone ensures uniform drying of the product, as the product gently tumbles while the cone rotates slowly. The diffusive action induced by the tumbling cone constantly presents a fresh layer to come into contact with the indirectly heated walls of the shell. Well designed sealing systems enable maintenance of deep vacuum inside the shell, and also ensures positive circulation of a heating media in the jacket.

A suitably sized condenser and receiver allows the solvent vapour to be totally condensed before being handled by the vacuum pump.

In addition, provision for purging the inner shell of the cone, with a suitable inert gas during its operation to evacuate the solvent fumes, totally prevents re-condensation of the solvent. This is particularly relevant towards the final stages of drying when the "Vapour Pressure Differential" between the cone and the vacuum receiver, is marginal and evacuation of the solvent fumes is inefficient by itself. Purging the system with an inert gas at this stage enables a quicker and better drying of the product.

SALIENT FEATURES UNIQUELY IN-COROPORATED IN OUR CONE DRYER

Location of Gland sealing arrangement right next to the shell.

Location of Gland sealing arrangement right next to the shell. Positive circulation of Hot Water is ensured with no chances of by-pass or short circuiting.

Positive circulation of Hot Water is ensured with no chances of by-pass or short circuiting. No Rotary Pressure Joints are used (which are the potential source of leakages).

No Rotary Pressure Joints are used (which are the potential source of leakages). Inert gas purging / pulsing is possible with vacuum "ON" (No need to shut-off Vacuum for Nitrogen admission).

Inert gas purging / pulsing is possible with vacuum "ON" (No need to shut-off Vacuum for Nitrogen admission).

OPTIONAL FEATURES

Condenser and Receiver

Condenser and Receiver Variable Speed Drive

Variable Speed Drive Hot Water System

Hot Water System Pneumatic Butterfly Valve

Pneumatic Butterfly Valve Lump Breaker

Lump Breaker Safety Barricades

Safety Barricades

CAPACITIES

Dryer available in capacities from 100 ltrs to 6000 ltrs.

Dryer available in capacities from 100 ltrs to 6000 ltrs.

* The design of the machine is subject to change from time to time to keep pace with the state of the art ensuring improvement in efficiency and elegance.