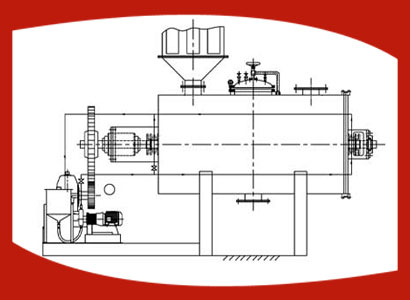

The Rotary Paddle Vacuum Dryer consists of a Stationary Cylindrical Shell mounted horizontally, in which a set of agitator blades mounted on a revolving central shaft stirs the solids being treated. Heat is supplied by circulation of steam, hot water or thermic fluid through the jacket, and also through the hollow central shaft and agitator arms. the agitator can be helical ribbons or paddle type.

The sweeping blades promoted product contact with the heated walls of the dryer, facilitate mixing and help achieve maximum blending and heating action. The hollow shaft and the paddle arms considerably increase the heat transfer area and thus a high heat transfer co-efficient is achieved.

The products are charged into the dryer shell through one or more number of ports situated on top of the shell. Vacuum is applied through necessary filters, condenser, vacuum trap, etc., by means of a water ring vacuum pump. Heat is supplied by steam / hot water / hot thermic fluid. Products at the end of the drying cycle are discharged through quick opening discharge port.

* The design of the machine is subject to change from time to time to keep pace with the state of the art ensuring improvement in efficiency and elegance.